Here’s how Ray Lloyd makes control line ends for stunt models – with notes added by Jim Hatch and Glen Alison.

Ray and Jim originally posted their notes on the Barton Forum

Right you will need round nosed pliers, nylon or terylene sowing thread, 1/16th OD copper tube

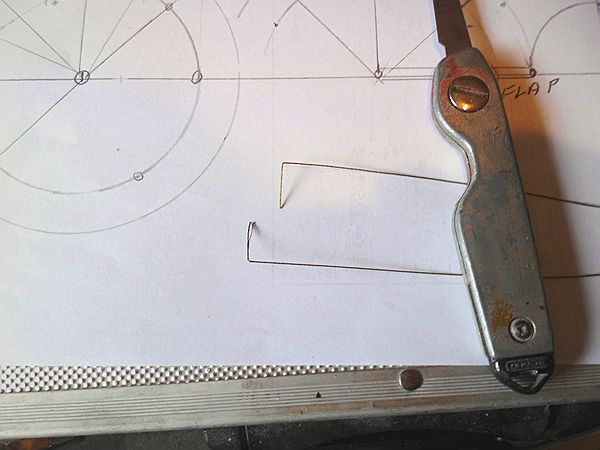

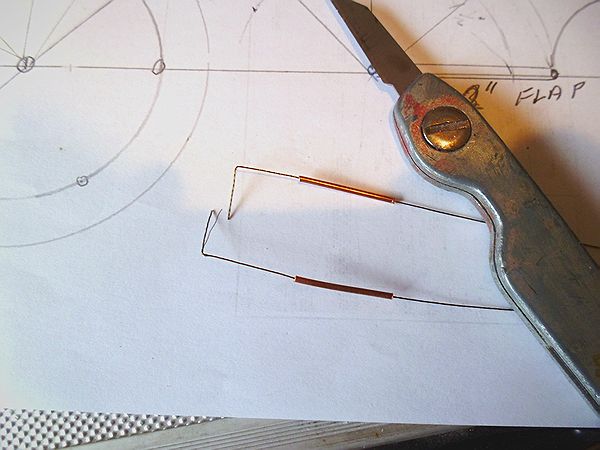

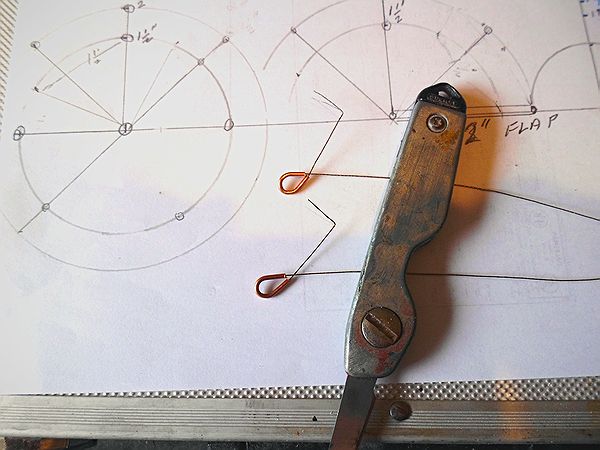

Thread 1in of copper tube on the line now bend a 1/2in leg on the line, slid the tube to 1in from the bend, bend tube to a pear shape, check again the distance from tube to the bent leg is 1in and adjust if needed, tie thread on the line at loop end and start to whip down the line, go 1/4in past the little leg, now start to whip back to the loop bending the leg towards the loop, at the copper tube fill the step to the tube with whipping (see pics) tie off and set with thin Cyano.

Ray

PS coat lines with a bees wax based polish and buff up.

Jim Hatch adds

One thing is for sure:-

Soldering the line ends is a recipe for disaster as I have seen on several occasions. If the solderer does not take extreme care to taper down the joint and if the line is less than 100% clean then they pile on the heat, changing the structure of the metal and also giving the inevitable “blob” of solder. Those lines will inevitably break at some point. The best solder joint uses the least solder.

I have said on several occasions that with the whipped ends I have not had a line break in over 20 years but I bow down to Ray’s better memory and it must be 30 years now. (and that is with stainless lines)

Crimps and solder ends are frowned upon by most aerobatics flyers.

Mine are always whipped with Terylene thread (thin but very strong) with thin cyano wicked into it.

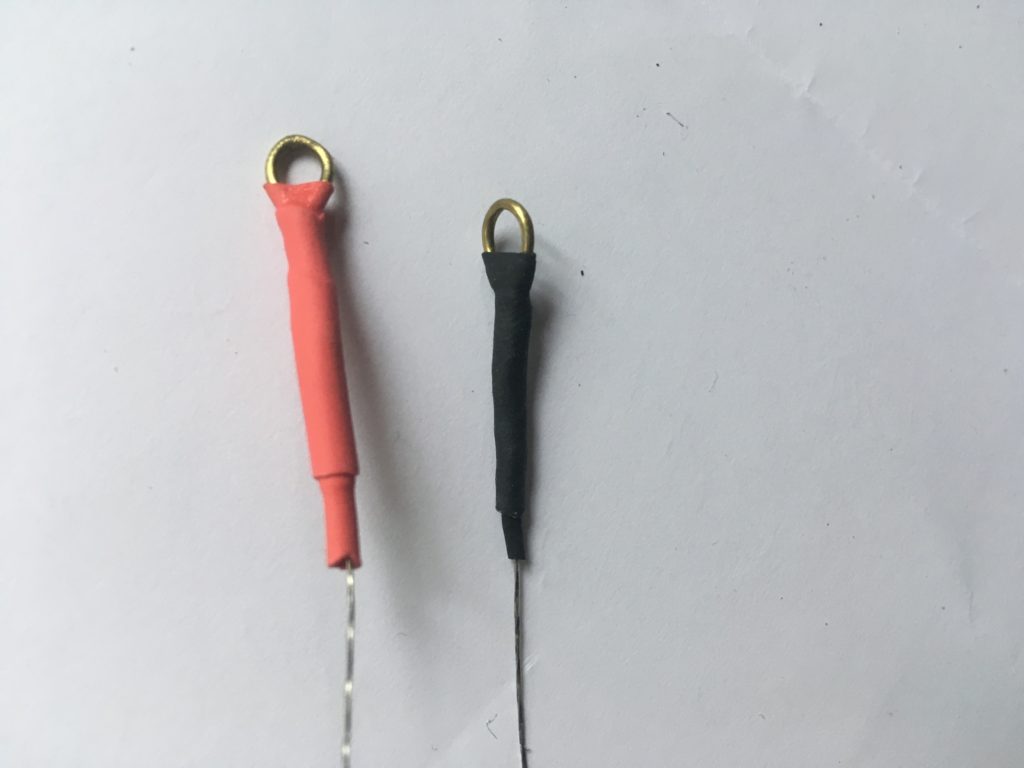

I now use a 50mm length of flexible tubing over the whipped end so as to produce a completely flexible end to my lines.

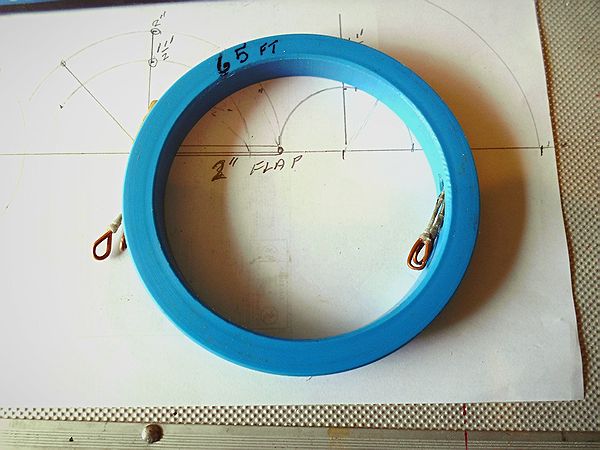

This is one that I made up last night. I have yet to gently squeeze the ring to make it oval. That line is 4 strand carbon steel. I put a short length of red heat shrink at both ends of my “up line” so that I don’t end up with lines reversed at the handle. (sure we have all done that at some time

A footnote from Glen Alison

I would only add that I reinforce the binding with some heat shrink that extends beyond the binding. This is the main contact point for your fingers as you repeatedly wrestle the line on to the connector ( flight after flight after flight!) Now I make my down line the Red one!